Fluidized mattress dryer has a high drying rate and the material is dried in an exceedingly small time. Materials remains totally free-flowing and uniform.

FBD bowl loading: In the tablet manufacturing method, The full operation of the Fluidized bed drier starts While using the loading of damp granular materials from your granulator. The soaked granules to generally be dried are put in the detachable bowl of the vertical FBD.

The polyester cartridge filtration is anti-static. Blowing of the lines with compressed air or washing with h2o.

This SOP is applicable in Production Area for use to drying of granulated materials all through producing of reliable oral doses types in pharmaceuticals.

Your browser isn’t supported any more. Update it to obtain the finest YouTube knowledge and our most recent characteristics. Learn more

Regular upkeep and cleansing of your fluidized bed devices are necessary to guarantee its successful operation.

The sucked air passes through a series of filters the place particles and impurities are taken off. The filtered air then proceeds to go through a heating program where by it’s heated to the desired temperature depending on the product’s prerequisites.

Learnaboutpharma is an e-Finding out System giving transformative education to pharma aspirants globally.

Hence, careful evaluation of each and every drying procedure is crucial to make sure website that the benefits is often capitalized, as well as disadvantages is often managed or mitigated.

Loading of components entails including a fresh batch of soaked granules in the product chamber by means of damaging tension feeding, materials may be sucked from your superior shear mixer chamber through a feeding tube.

The newest traits and improvements in Fluidized Bed Dryer engineering are the Electrical power Effectiveness Reigns by Squander warmth seize, optimized airflow, and hybrid drying with microwaves slash Vitality use, Automation with genuine-time monitoring and AI Management makes sure products quality and minimizes operator wants, Integrated Drying, coating, granulating and Pelletizing approach in a single device Strengthen performance and decrease dealing with and flexible configurations adapt to various elements and generation scales, maximizing versatility.

Heating Procedure: A heating program to raise the temperature from the drying air. This might include electrical heaters or steam check here coils. Exact temperature Command is vital to make certain the drying procedure is efficient with no compromising the integrity in the pharmaceutical product or service.

This could build perhaps problematic running conditions, leading to extra routine maintenance, prerequisite for dust elimination devices, and perhaps even problems with operator health and fitness and protection.

5. Right after some time, a degree of tension is achieved at which frictional drag to the particles is equal for the force of gravity.

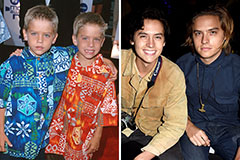

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!